Common Questions

Most Popular Questions

Find answers to some of the most frequently asked questions about our corrosion protection services.

The duration of the job depends on the size and scope of the project. We aim to complete all projects efficiently without compromising on quality.

Corrosion control involves the removal of corrosion or rust and applying coatings or linings with specified products to protect the surfaces.

We work at a fast pace while maintaining high-quality standards. Our experienced team is dedicated to meeting deadlines and delivering exceptional results.

We use specialized products like Sraxor and other specified requirements to ensure effective and long-lasting coatings.

Our largest projects typically involve Eskom shutdowns and pipeline corrosion control. These projects require extensive planning and execution to ensure optimal results.

We can perform abrasive blasting on a variety of surfaces including metal, concrete, wood, and brick. Each surface requires a specific technique to ensure effective cleaning and preparation.

Safety is our top priority. We use advanced equipment, follow strict safety protocols, and ensure our technicians are trained and equipped with personal protective equipment.

Yes, we specialize in applying coatings to industrial equipment to prevent corrosion and wear, thereby extending the lifespan of your machinery.

Turnaround time depends on the size and complexity of the job, but we aim to complete most projects within a few days to a week.

Yes, we offer on-site services for pipeline corrosion control, including sandblasting and specialized coating applications.

High-pressure cleaning removes built-up residues and deposits, improving the efficiency and longevity of heat exchangers.

We assess the environmental conditions, material type, and specific requirements of each project to recommend the most suitable coating.

Yes, we have the capacity and expertise to manage large-scale industrial projects, ensuring timely and high-quality service.

We offer high-pressure cleaning for various applications including heat exchangers, pipelines, tanks, and general industrial equipment.

Yes, we provide environmentally friendly coatings and cleaning methods to minimize environmental impact.

Ready to Protect Your Assets? Let's Start Your Corrosion Control Project Today!

With 19 years of experience, RML Specialized Blasting and Coating is here to provide high-quality abrasive blasting, coating, and HP cleaning services to meet your needs.

Take A Look At What We Offer

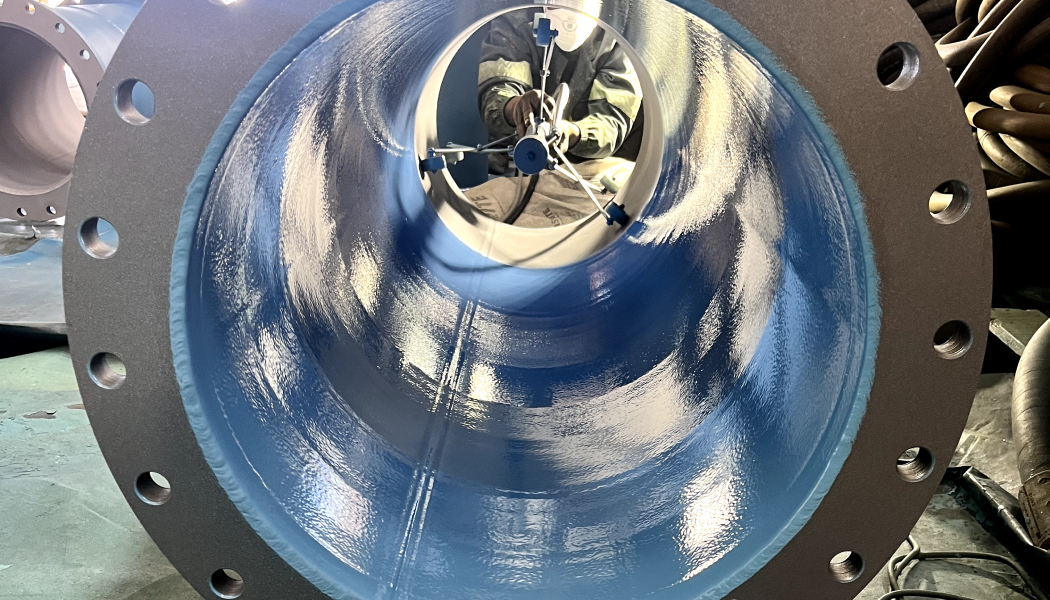

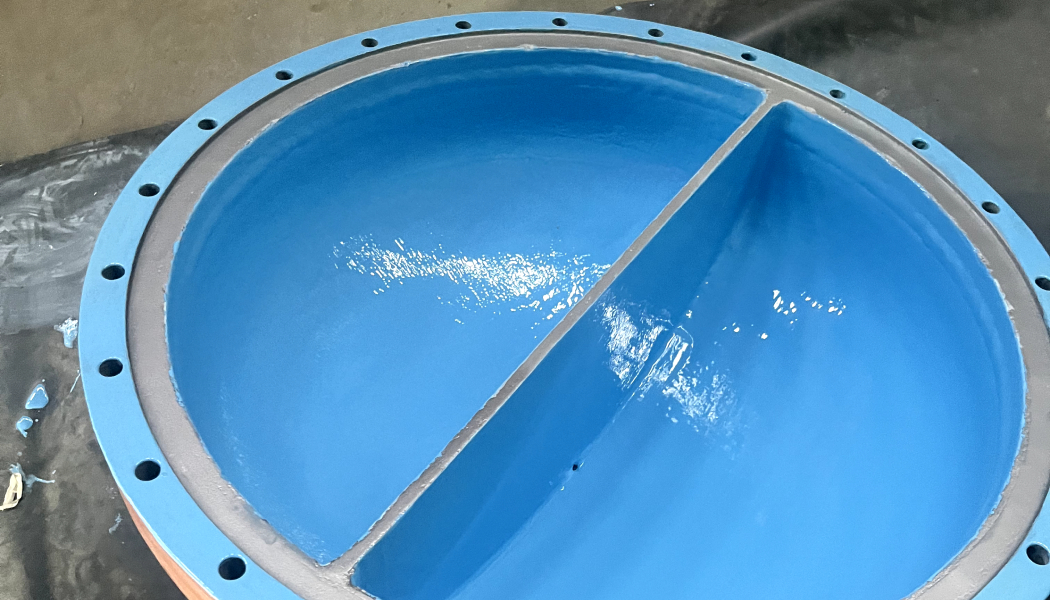

Pipeline coatings, epoxy coatings/linings to specifications.

Corrosion protection for heat exchanger tube sheets and supply of plugs for defective tubes.